Production of Damascus steel at a glance: A summary of the process

The fascinating world of Damascus steel has certainly piqued your interest, especially if high-quality knives are one of your passions. But what exactly is behind this melodious name?

Damascus steel, as a material for Damascus knives, has an attractive appearance, high hardness and sufficient flexibility at the same time. The manufacturing process is characterised by various details, whereby the processing of the steel makes an essential contribution to the quality of the Damascus knives.

History of Damascus knives

The history of knife production often arouses interest, and many sources suggest that it originated in the Orient. However, there is also evidence that the Celts used Damascus steel for their swords. Over time, the material became increasingly popular for knives. The elaborate production of Damascus steel became a traditional craft, and Damascus knives are now a speciality in the kitchen, prized by passionate chefs.

Steel Hardening in Manufacturing

One of the crucial aspects of knife production is the hardening of the steel. To ensure that the products achieve the desired hardness and can be used extensively in the kitchen, the hardening process must be carried out by a blacksmith. This involves relying on rapid cooling.

After the iron has been heated in the blacksmith’s fire, it is cooled rapidly in cold water or oil. In some cases, the degree of hardening is achieved by increasing the carbon content in the steel.

Combining Different Hardnesses

The Damascus knives are intended to be hard and flexible simultaneously. The art lies in achieving this balance. A sharp blade is primarily achieved through the use of hard steel. However, hard steel is quite brittle and can break more easily. Therefore, it is better to work and sharpen a blade made of soft steel. Since soft steel does not become as sharp, the hardness level of the steel must be adjusted. In Damascus steel, steel with different hardness levels is combined. Multiple layers of hard and soft steel are created and fused together through forge welding

Forge Welding

After heating the steel to various hardness levels, the smoothing process takes place, either through rolling or hammering. The resulting plate is cut and ready for folding. Folding, with as many layers as possible, influences the quality of the steel. Modern forges often utilize electronic welding devices that fuse the steel into a block. This block is flattened, folded, and heated again, with forge welding playing a central role.

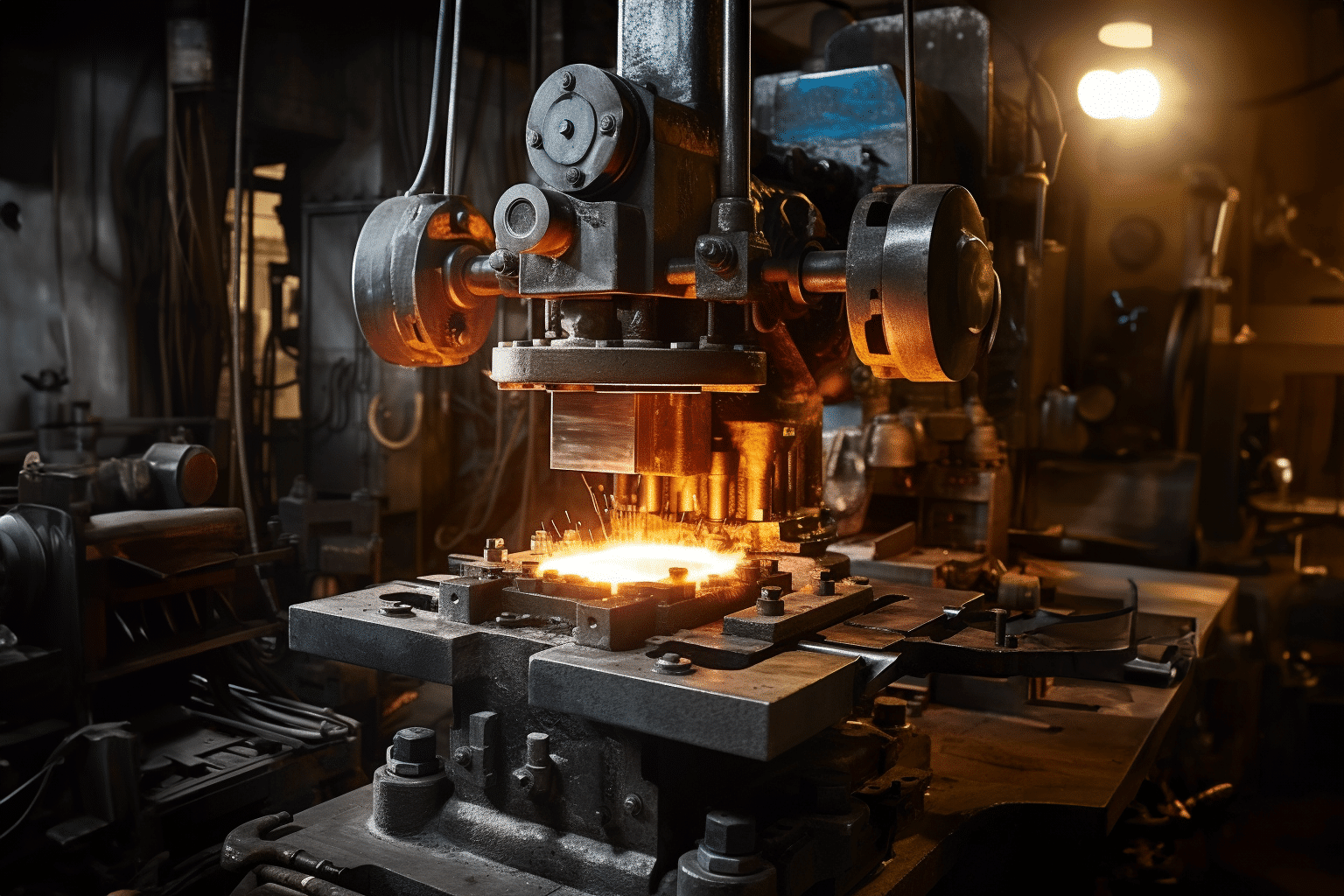

Pressing

The next step is pressing. This involves working with hammer blows to drive out surface oxides from the steel. Nowadays, this is typically done with an air hammer. However, in earlier times, mechanical hammers were used, requiring the use of water power.

Have you checked out our blog yet?

Here you can find a small selection of interesting blog posts

The art of handles: adelmayer’s masterpiece series with four fine types of wood

The art of handles: adelmayer's masterpiece series with four fine types of wood Choosing the right knife handle is a delicate matter that can have a major impact on the kitchen experience. adelmayer proudly presents the Meisterwerk series with handles made from four...

Masterful art: the creation of an 87-layer damask knife from adelmayer

"The Art of Damascus: Insight into the Production of an 87-Layer Damascus Knife by adelmayer" Before we delve deeper into the making of this impressive Damascus knife by Adelmayer, there's already an exciting blog article solely dedicated to the creation of Damascus...

Difference between a 67-layer Damascus knife and an 87-layer Damascus knife

Fine Nuances of Sharpness: What Makes 67-Layer and 87-Layer Damascus Knives Unique? Hello dear friends of masterful cutting art, Today, I invite you to dive into the fascinating world of Damascus knives with me and explore one of the central questions: 67 layers or...