“The Art of Damascus: Insight into the Production of an 87-Layer Damascus Knife by adelmayer”

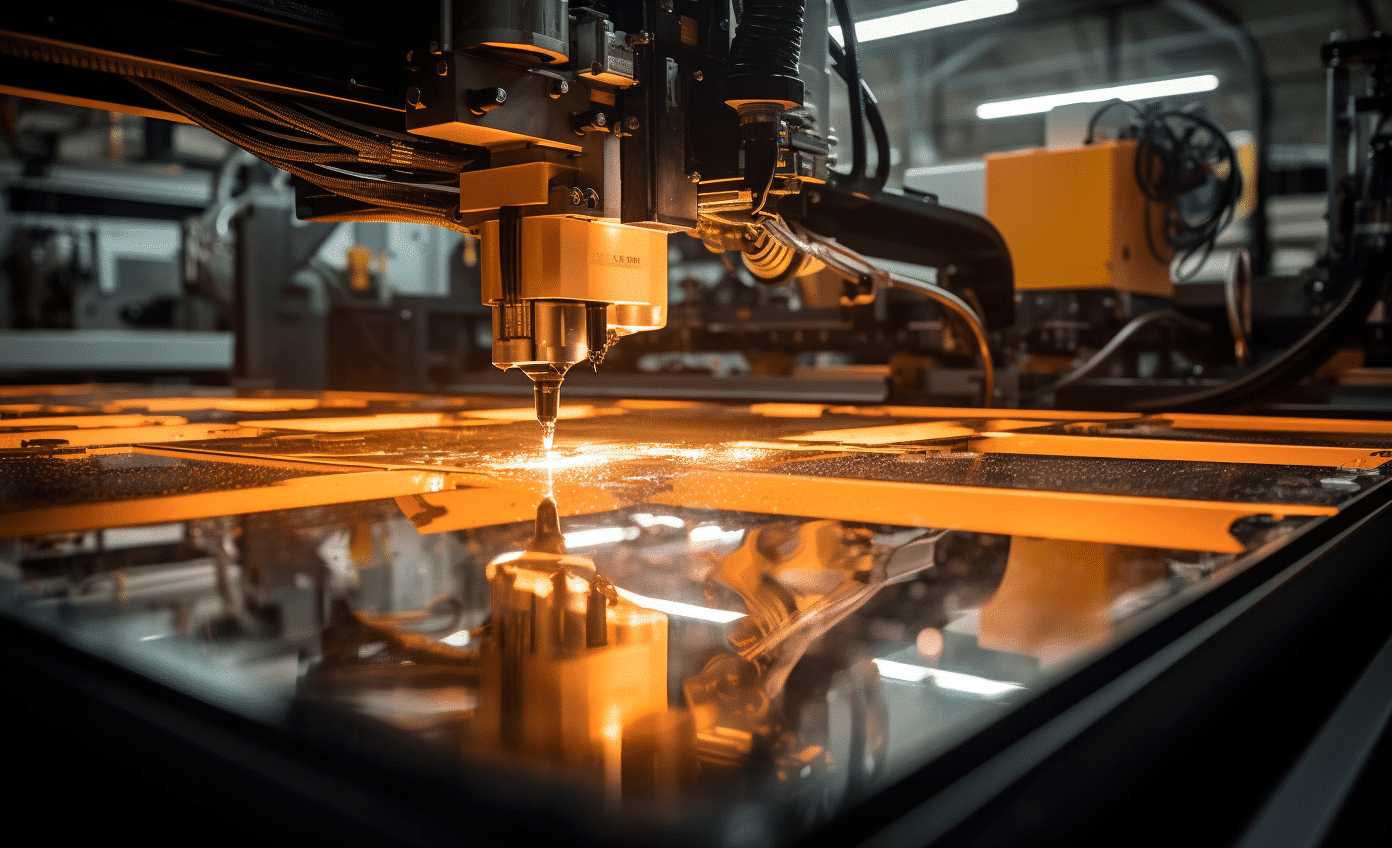

Laser Cutting

Here, a highly precise laser is employed to cut the stainless steel material into the desired shape of the knife with surgical precision. This technologically advanced step is controlled by a powerful computer, enabling the realization of even finely structured designs.

Compared to conventional pressing methods, laser cutting may take more time, but its application extends to demanding designs, small-scale productions, and prototypes. This process is distinguished not only by its technological sophistication but also by its ability to translate artistic visions into reality. Laser cutting marks the beginning of a meticulous manufacturing process based on the highest precision and state-of-the-art technology.

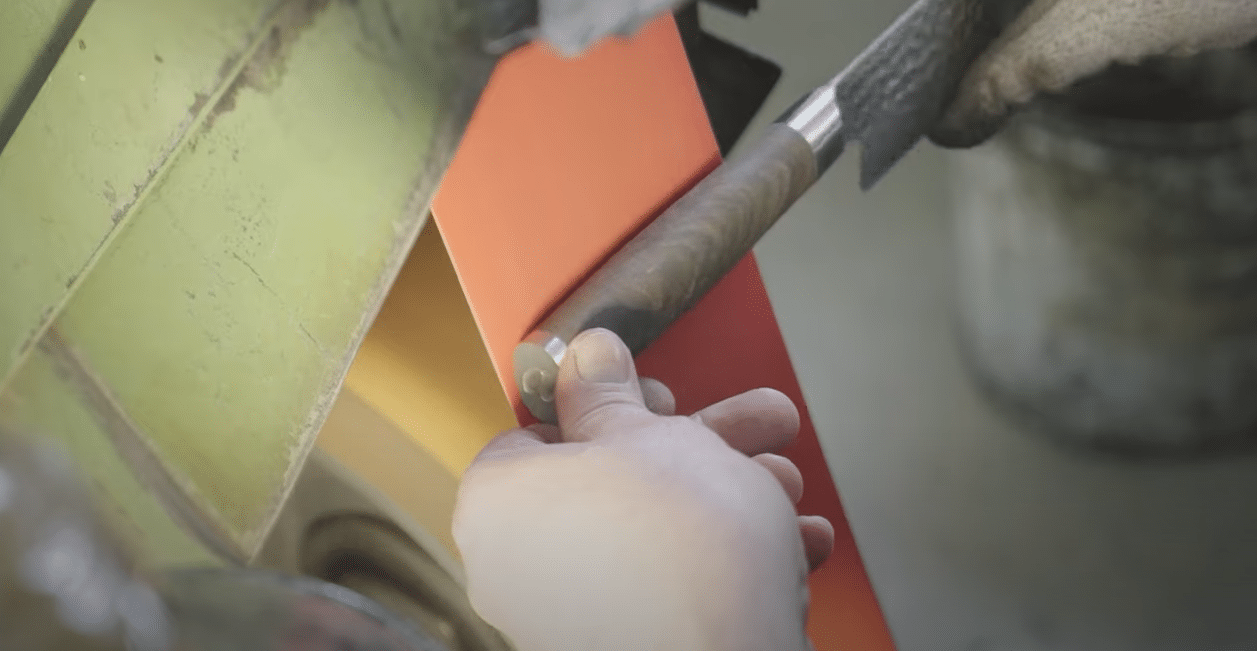

Bolster Welding

One pivotal step in the intricate process of Damascus knife crafting is bolster welding. Here, a bolster is welded to the blade to establish a sturdy and enduring connection between the blade and the handle. This welding transcends mere functional reinforcement and significantly contributes to enhancing the water resistance of the handle.

The meticulous execution of this artisanal masterpiece ensures not only a strong bond but also increased durability of the entire knife. By fusing the bolster and blade, not only is the structure of the knife strengthened, but its resistance to external influences is also heightened. Bolster welding is thus not just a technical step but also an artistic refinement that accentuates the quality and longevity of Adelmayer’s Damascus knife.

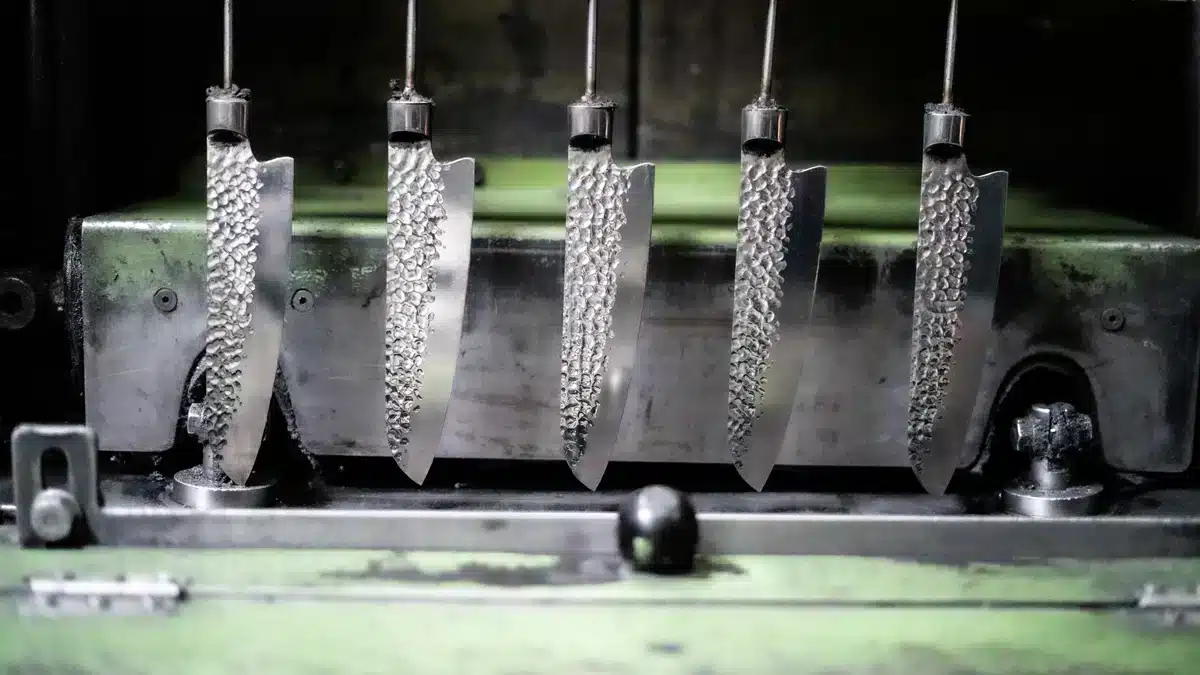

Surface Polishing / Grinding:

Using a special polishing wheel, the area surrounding the blade is worked on. This meticulous manual labor requires precision and experience to ensure that the knife’s surface exhibits flawless aesthetics. Subsequently, a computer-controlled machine takes over the task of adjusting the shape of the knife using a grinding stone. This step ensures not only a uniform contour but also highlights the individual details of the design.

The culmination of this artisanal process lies in the delicate grinding of the surface of the knife tip. This fine work is crucial for the manifestation of the characteristic Damascus pattern afterward.

Mirror Finish Polishing / Beam Grinding:

To achieve an even finer surface, the blade is carefully polished between two rollers until it achieves mirror reflection. This elaborate process not only gives the blade a shiny mirror finish but also emphasizes the fine details of the design. Thus, the knife becomes not only a highly precise tool but also a work of art that radiates elegance down to the smallest detail.

Each individual particle contributes to giving the knife a distinctive identity. Mirror finish polishing and beam grinding are thus not only technical steps but also artistic elements.

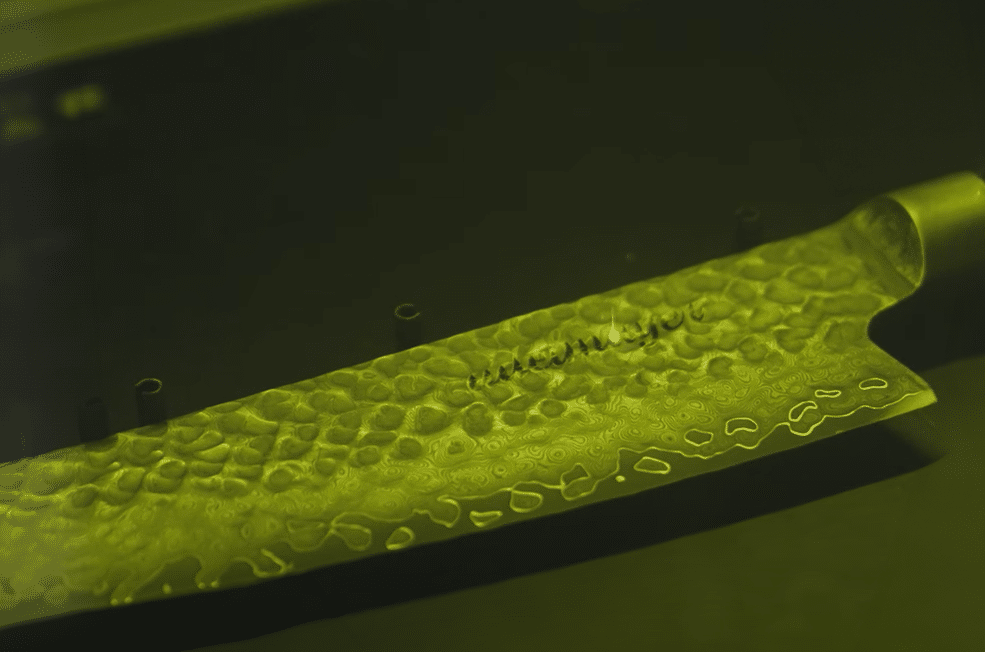

Etching

During the etching process of a Damascus knife, the prepared blade is immersed in an etching solution, which often contains acids such as hydrochloric acid or ferric chloride. These acids react differently with the various layers of Damascus steel. The etching solution emphasizes the contrasts between the layers and creates the characteristic pattern of Damascus steel. After achieving the desired degree of etching, the blade is neutralized, the etching mask removed, and the blade thoroughly cleaned. The etching process is crucial for the visual attractiveness and uniqueness of the Damascus pattern.

Assembly:

During the assembly of the Damascus knife by Adelmayer, utmost precision is applied. The handle and the rear bolster are carefully fitted to the blade, with the use of high-quality hardwood for the handles playing a crucial role. The wood not only emphasizes aesthetic elegance but also functional robustness. Additionally, targeted measures are taken to improve waterproofing, ensuring not only the longevity of the handle but also the overall quality of the knife. Assembly is a craftsmanship process that showcases the outstanding quality and attention to detail that goes into every Damascus knife by Adelmayer.

Wooden Handle Polishing / Bolster Polishing

The refinement of the wooden handle and bolster is an artistic step in the manufacturing process. The assembled handle, crafted from carefully selected hardwood, undergoes elaborate polishing to provide not only an aesthetically pleasing but also tactile experience. Specialized polishing agents are used here to accentuate the wood’s natural beauty while ensuring a smooth surface.

Laser engraving

Individuality is emphasised by precise laser engraving. Each knife proudly bears an engraved marking and the high-precision laser engraving guarantees a permanent and precise marking on the knife, emphasising adelmayer’s commitment to quality and craftsmanship. Each marking tells a story and gives each Damascus knife a unique identity that goes far beyond its functional excellence.

This process is not just a technical necessity, but an artistic expression of individuality and character. Laser engraving is one of the final elements that turns each knife into a personal work of art that carries the history of its craft and the uniqueness of its existence forever.

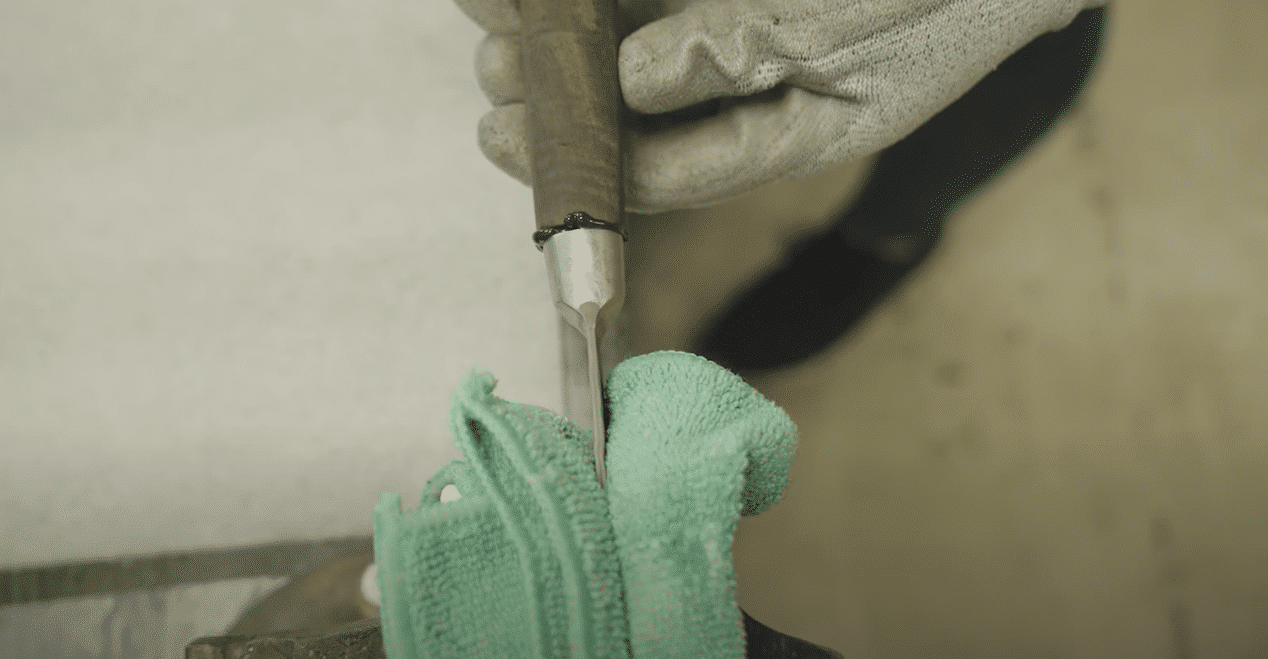

Sharpening the blade:

A final precise sharpening gives the Damascus knife its unrivalled sharpness, which is ensured by experienced craftsmen. This final step is crucial for the performance and quality of the end product.

The production of an 87-layer Damascus knife from adelmayer is therefore a symbiosis of craftsmanship, precision and dedication that produces a unique masterpiece.

Final phase Inspection & honing of the blade

Finally, burrs are removed using tanned leather. The sharpness and durability of the blades are checked individually, the blade angles are carefully checked and the finished knives are properly packaged. Immerse yourself in the art and precision that every 87-layer Damascus knife from adelmayer embodies.

Have you checked out our blog yet?

Here you can find a small selection of interesting blog posts

The art of handles: adelmayer’s masterpiece series with four fine types of wood

The art of handles: adelmayer's masterpiece series with four fine types of wood Choosing the right knife handle is a delicate matter that can have a major impact on the kitchen experience. adelmayer proudly presents the Meisterwerk series with handles made from four...

Production of Damascus steel at a glance: A summary of the process

Production of Damascus steel at a glance: A summary of the processThe fascinating world of Damascus steel has certainly piqued your interest, especially if high-quality knives are one of your passions. But what exactly is behind this melodious name? Damascus steel, as...

Difference between a 67-layer Damascus knife and an 87-layer Damascus knife

Fine Nuances of Sharpness: What Makes 67-Layer and 87-Layer Damascus Knives Unique? Hello dear friends of masterful cutting art, Today, I invite you to dive into the fascinating world of Damascus knives with me and explore one of the central questions: 67 layers or...